ENGINEERING DOCUMENTATION

►Safety Engineering with CE Certification

Our CE Certification documentation ensures that your manufacturing equipment, machinery, and even automated production systems meet the European safety standards required for automotive manufacturing. From robotic assembly lines to specialized production tools, we provide thorough risk assessments, machine safeguarding protocols, and compliance documentation in line with the Machinery Directive and other applicable EU standards. This guarantees that your production processes not only meet safety requirements but also run efficiently with minimal risks to operators.

►Process Failure Mode and Effects Analysis (PFMEA)

In the fast-paced automotive industry, even minor process failures can lead to costly recalls or production downtime. Our PFMEA services are specifically designed to address automotive manufacturing challenges, analyzing critical processes such as assembly lines, supply chain logistics, and component manufacturing. By identifying potential failure modes in areas like welding, painting, and part assembly, we help you prioritize actions that prevent defects and ensure compliance with IATF 16949 and ISO 9001 standards. This comprehensive approach minimizes defects, enhances reliability, and boosts overall product quality.

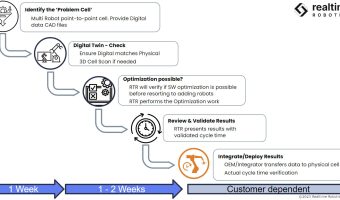

►Robot Safe Documentation

Our Robot Safe Documentation covers the safety and regulatory aspects of robotic systems commonly used in tasks such as welding, painting, part handling, and assembly. We assess your robotic applications against industry-specific safety standards like ISO 10218, ensuring that human operators and robots can work together safely and efficiently. We document the necessary safety measures, including cages, light curtains, and emergency stop systems, all while enhancing productivity on your automotive production line.

►MTM Studies

Our MTM studies focus on analyzing and optimizing the time required for each task in processes like vehicle assembly, component manufacturing, and supply chain operations. We offer detailed documentation that pinpoints inefficiencies, enabling you to streamline production processes while reducing waste. This service helps automotive manufacturers reduce costs and meet the high demands of just-in-time production. Our MTM studies are aligned with the need for precision and speed in the automotive sector, helping you balance quality and cost-effectiveness.

►Ergonomic Studies

Our ergonomic studies focus on reducing fatigue and improving the efficiency of your workforce by optimizing the design of workstations, tools, and workflows. Whether it’s designing assembly stations for minimal strain or ensuring that manual handling tasks comply with industry standards, we help you protect your workers from long-term injuries while increasing their productivity. With a focus on automotive-specific tasks, we ensure that the ergonomics of each role in the production process is optimized for safety and comfort.

►Plant Operating Instructions

Our Plant Operating Instructions are designed to ensure smooth operations in automotive manufacturing plants, where precision and coordination are key. We create clear, detailed instructions for operating complex machinery, from robotic arms on assembly lines to paint booths and CNC machines. These instructions include essential details on setup, operation, maintenance, and safety procedures, helping your team avoid costly errors and ensuring compliance with ISO 45001 standards. Tailored to your specific automotive production processes, our documentation ensures that every part of your plant runs safely and efficiently.

FEATURED COMPETENCIES

Safety Engineering

Safety Engineering

CE Documentation

PFMEA

Robot Safe Documentation

Methods Time Management

Ergonomic Studies

Plant Operating Instructions

General Project management

SOFTWARE COMPETENCIES

MTM

![]() KUKA Safe

KUKA Safe

Robot Safety

Process Simulate

RELATED COMPETENCIES